Part 2

A Closer Look at Hard Disk Drives

Chapter 3

Inside Hard Disk Drives

How They Work

The purpose of a hard disk drive is to store computer data and instructions in the form of binary numbers - the two distinct magnetization patterns which define digital computer information as 1s and 0s. The source of the data and instructions is any software program that involves the computer's central processing unit (CPU) working in conjunction with various periph-eral components, including the hard disk drive itself.Hard disk drives store data in a form that is compact, easily and quickly accessible, reliable, and cost effective. Manufacturers are constantly refining and improving hard disk drives to take advantage of the latest breakthroughs in a wide range of scientific and engineering disciplines, including mechanical and electronic engineering, chemical engineering, and even aerodynamics. Far from being simple commodity components, today's hard disk drives represent a unique and powerful synergy of diverse technologies working in concert.

A Jukebox for Data

Although a hard disk drive is the most complex component in a personal computer in terms of moving parts, its mechanical operation is actually quite straightforward. As mentioned earlier, in many ways a hard disk drive operates like a music jukebox. Inside the drive's case are one or more constantly spinning aluminum-alloy platters, arranged one on top of another in a stack. When you are at work on your computer, you enter commands through your keyboard or mouse. The hard drive's actuator arm - much like a jukebox's tone arm - responds to these commands and moves to the proper place on the platter. When it arrives, the drive's read/write head - like the needle on the tone arm - locates the information you've requested. The head reads, or retrieves, the information, transfers it to the CPU, and in short order, the data you requested either appears on-screen, is queued up for printing, or is sent whirring across phone lines in the form of a fax or modem message.

Reading and Writing the Digital Way

While the jukebox analogy holds for a hard drive's mechanical operation, the way in which hard drives write, store, and read data is more like the way an audio tape recorder works. Audio tape is coated with a thin layer of microscopic metallic particles. Sounds are recorded onto the tape by a recording head. These sounds are played back by a play head. Both the recording and play heads contain a small coil of wire through which electrical currents flow in continuously changing patterns that represent the sounds. As the tape passes under the recording head, it is magnetized by these currents. As it passes under the play head, the magnetic patterns are picked up, translated into audio data, and then passed to the amplifier and loudspeaker.

Data is written to and read from hard drives in much the same way. Like audio tape, hard drive platters are coated with a magnetic material a few millionths of an inch thick. But unlike an audio tape recorder, a disk drive uses a single read/write head to both write to and read from the disk.

To write information to a hard drive, an electrical current flowing through a coil in the read/write head produces a magnetic pattern in the coating on the media's surface corresponding to the data being written. To read information from a hard drive, the read/write head converts the magnetic patterns recorded on the media to an electrical current which is amplified and processed to reconstruct the stored data pattern.

Disk drives also differ from audio tape devices in the way in which data is stored. On tape, sound is recorded in continuously changing, analog patterns. On a hard drive, data is recorded as electrical signals. These signals are numerically expressed as 1s and 0s in the two-digit binary system described earlier.

The magnetic coating on the hard drive is composed of microscopic areas called domains. Each domain is like a tiny magnet with two opposite poles (a positive and a negative). Before recording data, the drive uses the read/write heads to orient the domains in a small region so that the magnetic poles all point in the same direction. Then, the hard drive uses the read/write heads to record data. While all 1s could be recorded as a region with the positive pole to the left and all 0s with the positive pole to the right, the hard drive uses a more efficient recording method called flux reversal. Whenever the drive encounters a 1, the read/write heads reverse the magnetic pole direction. Whenever the drive encounters a 0, the read/write heads do not change the magnetic pole direction.

Hard disk drives record data in tracks, or concentric circles, that are numbered from the outermost edge of the disk to the innermost. The hard drive is a random access device: it can retrieve the stored data anywhere on the disk in any order. (By contrast, sequential access devices, such as audio tape recorders or tape backup systems are not as quick to retrieve data. They move to a new location on a tape by fast forwarding or rewinding the tape.) A hard drive's read/write head can literally fly directly to a new location once the CPU provides the address. The ability to randomly store and retrieve data is the most important reason disk drives rapidly displaced tape as the primary computer storage technology.

Hard disk drives can record data on both sides of a platter if read/write heads are positioned on each side. For example, a hard drive with two platters could have up to four data storage surfaces and four read/write heads; a hard drive with three platters could have up to six data storage surfaces and six read/write heads; and so on. The drive actuator arm synchronizes all the read/write heads so that they stay in perfect alignment as they move together across the platter's surface.

The platter's surface is organized so the hard drive can easily find data. The concentric tracks are divided into units called sectors. (For more information, see "Disk Geometry" later in this chapter.) Information is recorded on the outermost track of all platters first. Once the outside track is filled up with data, the heads move inward and begin writing on the next free track. This recording strategy greatly boosts performance since the read/ write heads can record more data at one position before having to move to the next track. For example, if the read/write heads in a four-platter drive are positioned on track 15, then the drive writes to track 15 on both sides of all four platters before moving the read/write head inward to track 16.

The design of hard disk drives makes them quite fast - much faster than either tape or floppy diskette drives. What's more, unlike floppy drives, hard drives virtually eliminate friction between the disk and read/write head, further speeding performance and reducing wear on the heads and media. When you turn on your desktop computer, the platters in your hard disk drive immediately begin spinning at 3,600 rpm or higher. They remain spinning until you turn the computer off or it loses power. This rapid spinning creates a tiny cushion of air above each platter, permitting the tiny read/write heads to float, or fly, just above the surface.

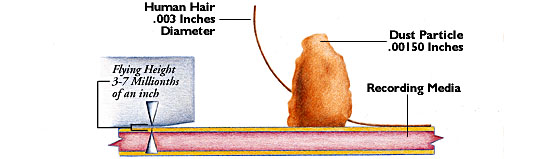

What's remarkable is that the read/write heads are precisely designed to fly just a few microinches above the surface of the platters - a space considerably thinner than a shaft of human hair or even a particle of smoke. Despite the speed and tolerances involved, the heads never touch the surface of the platters while the disk is spinning. When the system is turned off, the platters stop spinning, and the read/write heads touch down in a designated landing zone, separate from the area on the platters where data is stored. If contamination or severe shock cause the heads to touch the surface, or "crash," the heads or data surface can be damaged, data lost, and, in the most extreme cases, the drive can even be rendered inoperable. In today's advanced drives, however, crashes are rare because drives are tightly sealed to keep out contaminants and built to withstand shocks in the range of 70 to 100 times the force of gravity (70-100 Gs).

//

A Closer Look at Drive Construction

As mentioned previously, the part that gives a hard disk drive its name is a rigid aluminum-alloy disk, or platter. Although some hard drives use only a single platter, most use two or more platters in a disk stack assembly on a common spindle.

The hard drive's spindle motor rotates the platters counter-clockwise at speeds currently from 3,600 to 7,200 revolutions per minute (RPM). Drives used in desktop PC and workstations rotate continuously as long as the host system power is on, even when they are not reading or writing. Drives used in battery-operated laptops and notebooks have several power saving modes to prolong battery life. For example, the "sleep" mode causes the hard drive to stop spinning after a certain period of idle time. During the sleep mode, the drive's electronics remain powered up to provide a fast restart when the computer accesses the hard drive.

The 1s and 0s that comprise the information on a disk are stored as a magnetic pattern in the magnetic coating on the disk. The read/write heads generate these patterns in writing data to the disk platters. Then, when reading from the disk, the read/write head converts the stored magnetic patterns to electrical signals representing the stored data. Hard drives usually have a read/write head on each side of a platter. Each head is held in place by an actuator arm. The combined assembly of heads and disks is often referred to as the head disk assembly or HDA.

The actuator arms, and thus the read/write heads, are moved by a positioning motor, which is controlled by the disk controller. Today's sophisticated drives rely on a positioning technology, called closed-loop positioning, in which positioning information is fed back to the controller electronics, which direct the motor to readjust the position of the read/write heads accordingly. Closed-loop positioning technology ensures highly accurate reading and writing of data.

The signals that a read/write head picks up from a platter are very weak. The read preamplifier and write driver circuit, mounted on a flex circuit inside the HDA, increase the strength of the signals so that chips on the printed circuit board (PCB) can convert this electrical impulse to a digital signal. The PCB contains the drive electronics which are part of the drive assembly. The drive electronics include:

- A digital signal processor (DSP) to convert the incoming electrical signals to digital signals

- Spindle and actuator motor controller electronics to ensure that the platters spin at the correct speed and that the actuator arms place the read/write heads over the precise spot on the platter

- Interface electronics to communicate with the system's CPU in the proper format

- A microprocessor and associated memory chips to oversee drive operations

The microprocessor and memory electronics on an advanced drive are highly sophisticated; for example, high capacity drives have on-board processing power equivalent to the entire computing power of the first PC/ ATs. The base casting is a single piece of aluminum that provides an enclosure for the HDA and a mounting for a PCB. A gasket between the base casting and the top cover acts as a seal to provide a contamination-free operating environment for the read/write heads.

The link between the disk drive and the system bus is through the bus interface connector which takes signals from the drive's interface electronics and passes them to the I/O bus of the host computer. From there, the information is part of the electronic world of the CPU, available to be viewed, printed, edited, and returned again to the hard drive.

//

Flying Height Comparison

Go Back Go To Contents Go Forward

Storage Basics

| Newsgroups and FAQ's | Standards

Activity | Current Research Products | Employment | Support | Corporate | Doing Business | Quantum Store

|